From measurement to operational biofouling intelligence

FOCUSED ON SWRO OPERATIONS

- Early biological instability detection. Identifies developing biofouling risk before conventional indicators respond.

- Continuous, autonomous operation. Designed for harsh intake and pretreatment environments with minimal intervention.

- Operational integration. Structured data for SCADA,PLC historian systems and real-time alerts.

- Decision enablement, not reporting. Supports controlled intervention before CIP escalation and membrane damage occur.

Operational impact at plant scale

Measurements per day from 1 sensor

Simultaneously measurable parameters

Datasets in database already analysed

Biofouling-relevant water quality indicators with SM One

Continuously monitored signals relevant to SWRO intake and pretreatment stability include:

- Chlorophyll α and β – Indicators of photosynthetic activity and biomass dynamics.

- Phycocyanin – Cyanobacteria signal relevant for bloom detection.

- Dissolved organic matter (DOM) – Organic load contributing to biological fouling potential.

- Total organic carbon (TOC – relative signal) – Detectable organic carbon trends (site calibration required for absolute values).

- Water optical turbidity / organic TDS component – Combined organic and fine particulate signal.

- Water temperature – Operational parameter influencing biological activity and membrane performance.

- Surface oil presence (optional setup) – Binary detection when configured near surface.

- Salinity / conductivity (optional add-on) – Under extended calibration (current development stage).

List is constantly expanding – use the button below to download the latest up to date data with the full list of currently available parameters.

How we do it

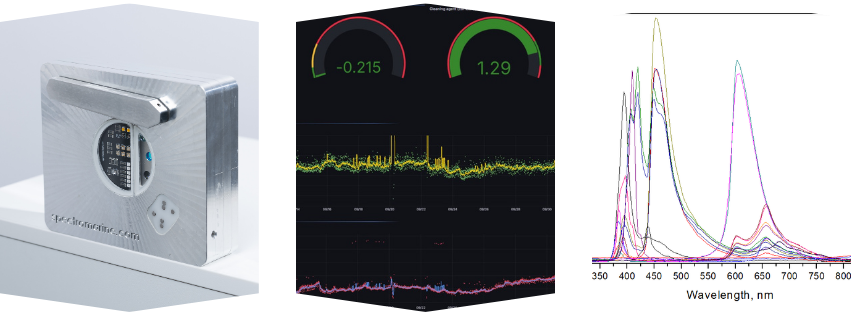

Hardware

Carefully chosen optical system combines filters, LEDs and detectors. From CAD to PCBs, optical systems, electronics and waterproof cases – all tailored get most robust and versatile operation. Full spectrum measurements with outstanding dynamic range and sensitivity, all made with different excitation wavelengths.

Software

Full automation – designed with remote operation and data collection in mind. Auto-calibration, data acquisition, data management and storage. “plug-and-play” – no need for data loggers, servers and vsualization

Database

Sensor is tested in a controlled laboratory environment – with predetermined concentrations of components (Chlorophyll, Phycocyanin, Carotenoids etc.) inside water with varying dissolved organic matter (DOM) amounts. Data from all sensors is collected with blocks of metadata for ease of deployment in the future

Other applications for our technology

Aquaculture

In 2023, Spectromarine completed its first pilot deployment with a top global shrimp producer, validating the system in a large-scale aquaculture environment. Continuous monitoring of biological and organic water indicators supports feed optimisation, operational stability, and reduced risk of sudden water quality-driven stock losses.

Mining

Technology is also being piloted in post-mining water environments in collaboration with RAG (Germany), where continuous monitoring of dissolved organic matter and related indicators supports long-term water stability management. These deployments demonstrate the system’s robustness in complex industrial water conditions beyond desalination.

Environmental studies

As part of the “Lakes Go Digital” project, Spectromarine sensors are deployed on floating buoys in urban lakes across Latvia and Lithuania to provide continuous monitoring of chlorophyll and dissolved organic matter. These deployments support early identification of phytoplankton bloom development and enhance real-time environmental decision-making for public recreational waters.

Team

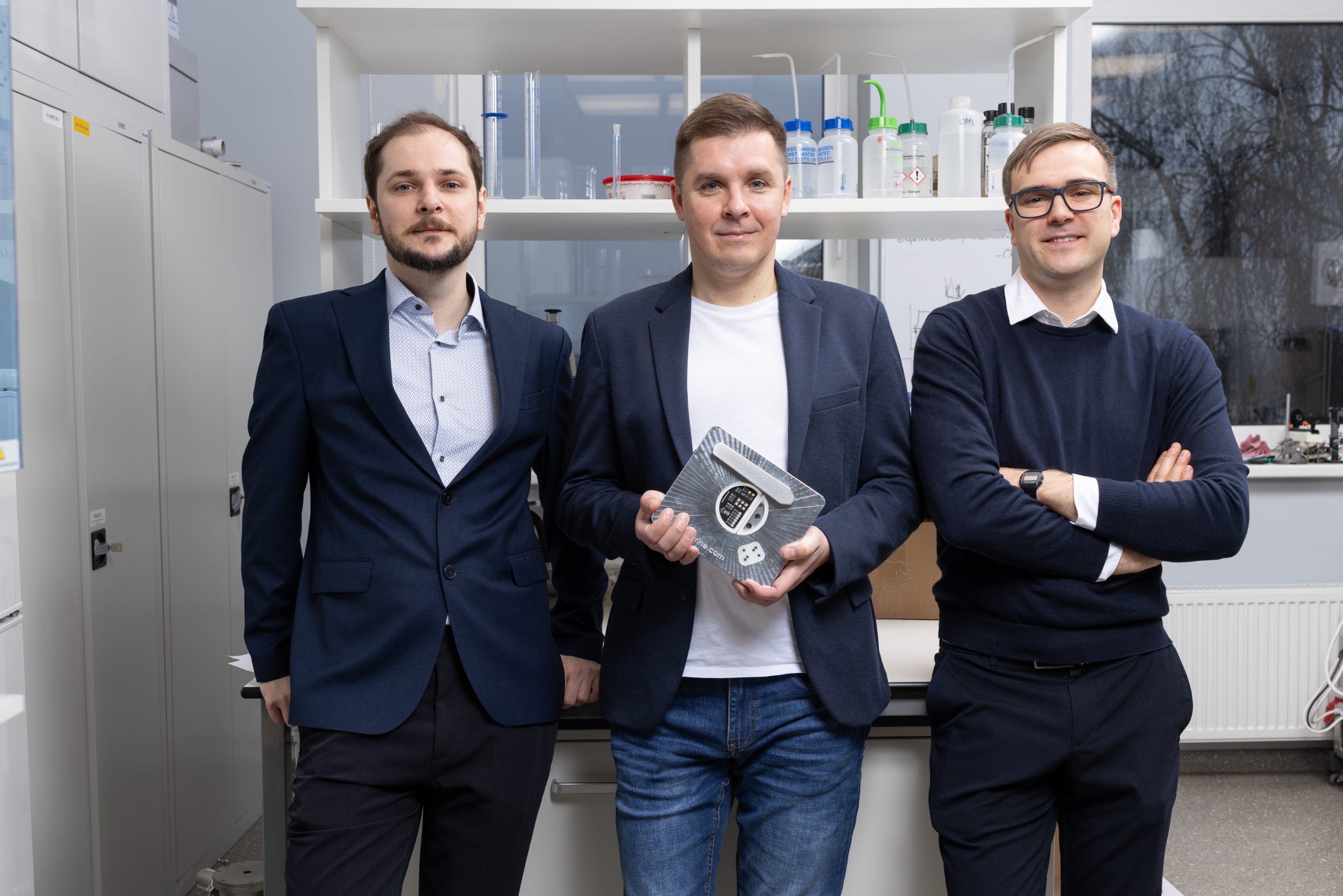

MSc.phys Gatis Tunēns- CTO (Chief Engineer)

Researcher, electronics and optics engineer with over 5 years in R&D of optical systems.

MBA Ģirts Ozoliņš- CEO (Business leader)

More than 15 years in business development, specializing in deep-tech commercialization and startup management. Co-founded 3 companies.

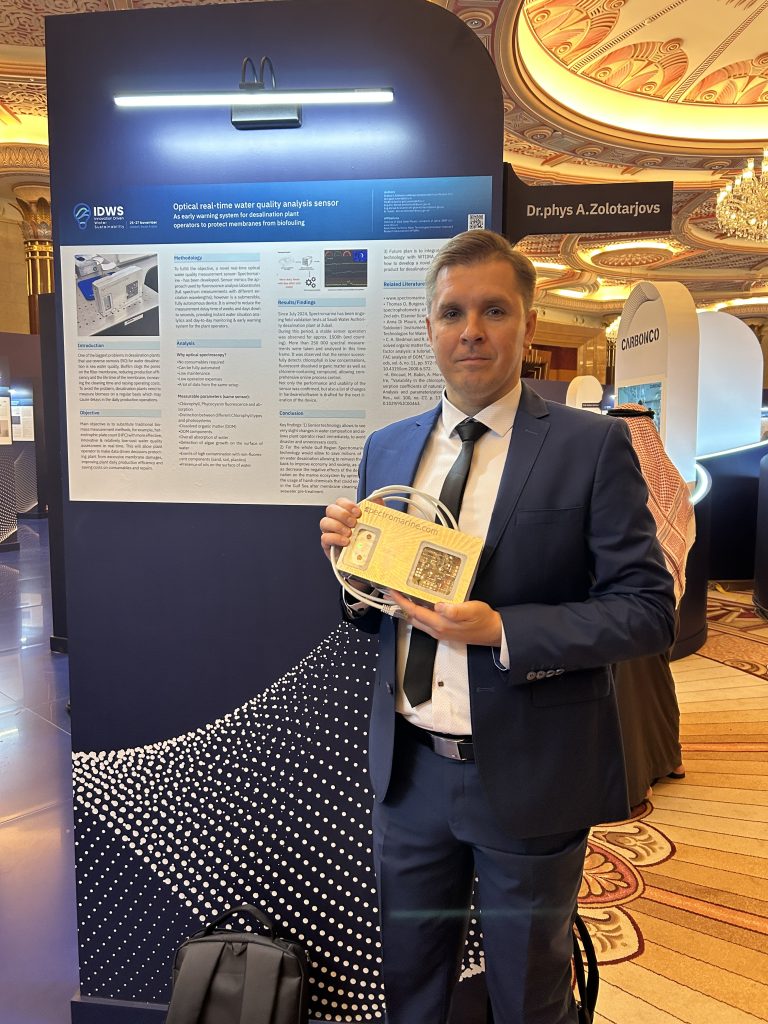

Dr.phys Aleksejs Zolotarjovs – COO (Scientific Leader)

Over 10 years in R&D of optical systems, with extensive experience in luminescence research and project leadership. Head of optical materials laboratory.

For enquiries please contact Mr.Girts Ozolins: go@spectromarine.com

Subscribe to our newsletter

Get access to updates on the development progress, acquired data and news – subscribe to our newsletter and we will regularly send you a snippet on how thins are going.